OEM High Pressure Die Casting Aluminum Perfume Cap

Overview Custom Service Aluminum Alloy /Zinc Pressure ADC12 Die Casting Parts 1, Aluminium die casting is a process of i

Overview

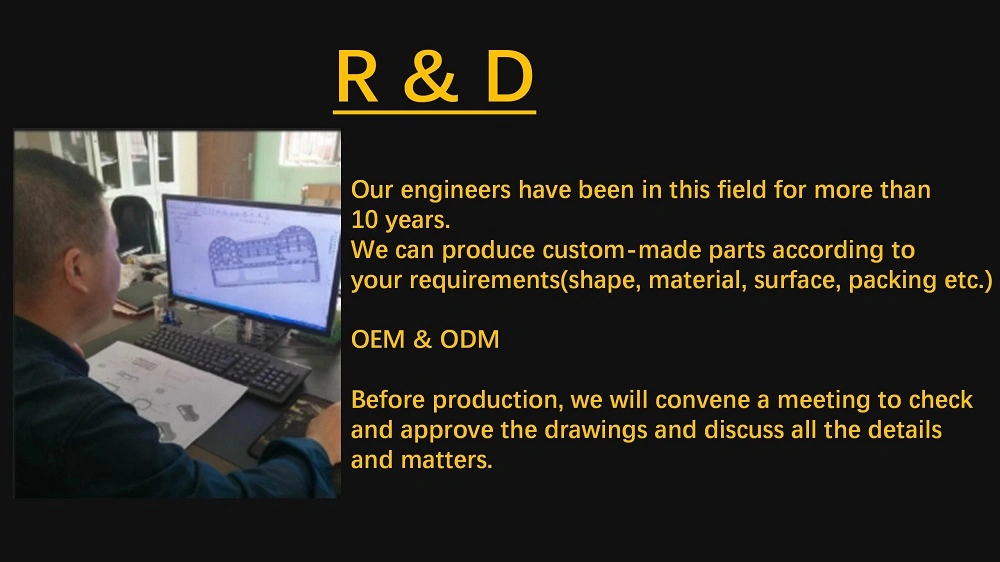

2, There are two processes of Aluminum die casting: hot chamber and cold chamber.3, A complete cycle can vary from one second for small components to minutes for a casting of large part, making aluminium die casting the fastest technique available for producing precise aluminium alloy parts.4, Qingdao Xinghe Machinery Company Limited ---we have a strong and highly efficient R&D team, which will design and make OEM/ODM products according to your drawings and samples.

5, Certification: TS16949, ISO9001, SGS, ROHS

Basic Info.

| Model NO. | Die Casting |

| Pressure Chamber Structure | Horizontal |

| Tolerance Grade | 4 |

| Casting Surface Quality Level | 1 |

| Certification | RoHS, ISO 9001:2008 |

| Weight Range | 0.003kg-30kg |

| Quality Certification | ISO 9001:2008, ISO16949 |

| Delivery | 30 Days Delivery |

| Other Material | Brass, Zinc, Zamak |

| Process | Die Casting+ CNC Machining |

| Surface Finish | Polishing, Anodising, Powder Coating etc |

| Product Name | Aluminum/Copper/Zinc/ Die Casting |

| Technology | High Pressure Die Casting |

| Transport Package | Wooden Crate or by Customer′s Requirement |

| Specification | Customized |

| Trademark | XH |

| Origin | Qingdao China |

| Production Capacity | 2000tons/Year |

Product Description

Custom Service Aluminum Alloy /Zinc Pressure ADC12 Die Casting Parts

1, Aluminium die casting is a process of injection aluminum alloy under pressure, which produces parts in high volume at low costs.2, There are two processes of Aluminum die casting: hot chamber and cold chamber.3, A complete cycle can vary from one second for small components to minutes for a casting of large part, making aluminium die casting the fastest technique available for producing precise aluminium alloy parts.4, Qingdao Xinghe Machinery Company Limited ---we have a strong and highly efficient R&D team, which will design and make OEM/ODM products according to your drawings and samples.

5, Certification: TS16949, ISO9001, SGS, ROHS

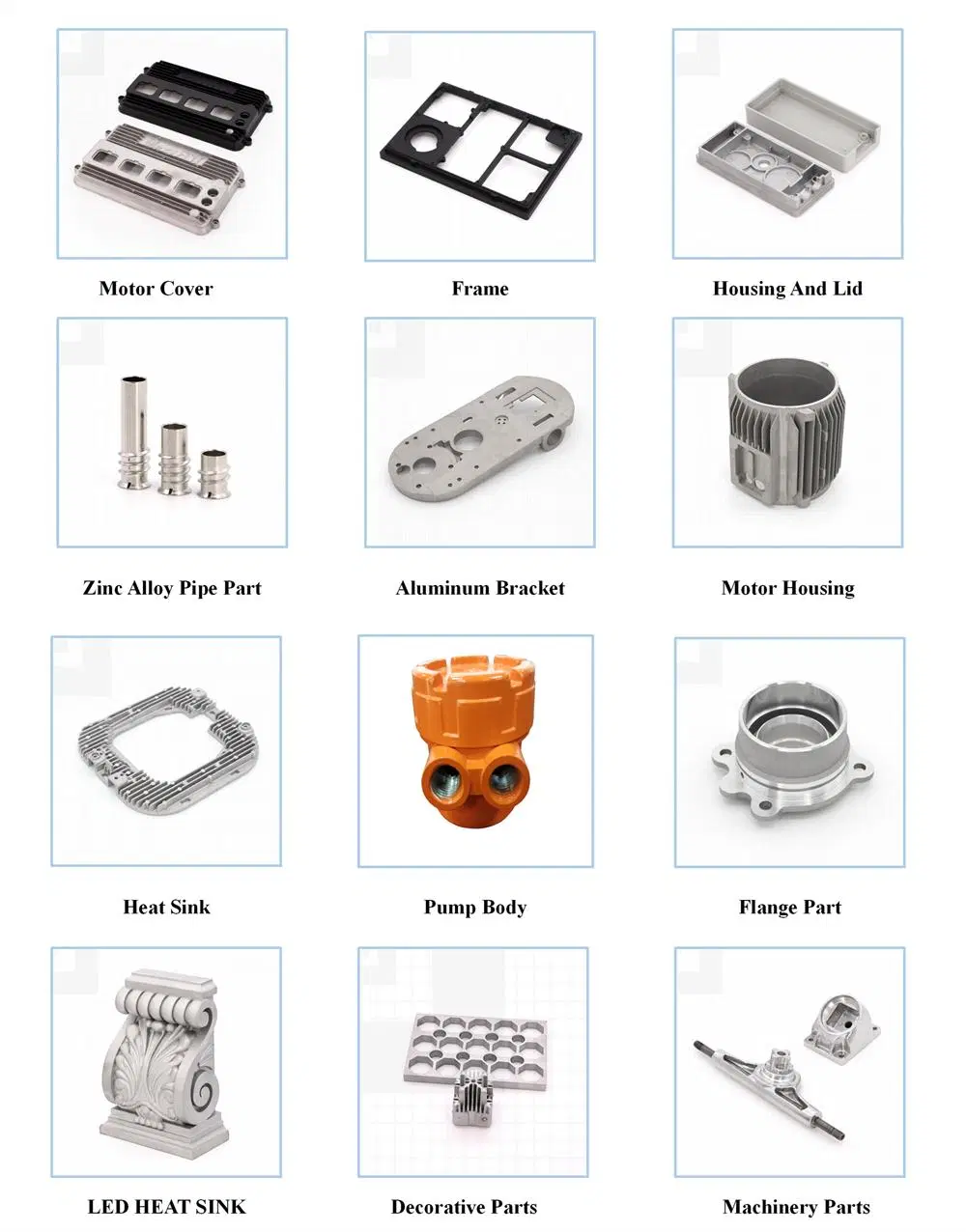

Aluminum Zinc die-casting products are characterized by high quality, light weight, high hardness and nice appearance.Therefore,aluminum die casting products are widely used in the automotive field. For example, Heat sink, Engine cooling fan, Water pump housing, end cover, air condition housing etc.

Product Description| Name | High Pressure Aluminum Zinc Die Casting Parts |

| Material | ADC12, A380, A356, ADC10, Zinc Alloy Zamak |

| Dimension | Mini 20*20 mm, Max800*800 mm |

| Technology | High Preressure Die Casting, CNC, CMM Measure, Painting, X-Ray Detection |

| Processing | 1, Sign Drawing (General clients provide the drawing or samples)2, Opening the Mold3, Die Casting ( Aluminium or Aluminium Alloy)4, Precision Machining (Burring, Lathe, Milling, etc)5, Surface treatment: Polishing, Electroplating, Sandblasting, Anodizing6, Inspection and Packing |

| Application | Automobile 42%, Furniture 21%, Industry 18%, Lighting 15%, Other 4% |

Send to us